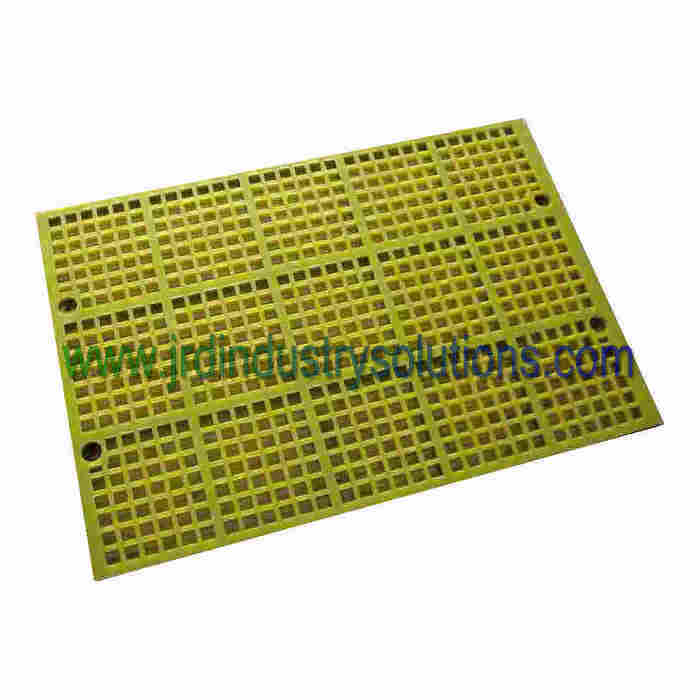

Modular Screen Panels Is a Kind Of Screening Rubber Or PU Mesh Used For Screening Solid Particles And Separating Large And Small Particles. Our Company Mainly Supplies Modular Rubber Screen Deck And Polyurethane Modular Screen Media. Wear-Resistant Rubber Is Mainly Used For Screening Under Drying Conditions, And Polyurethane Is Mainly Used For Wet Working Conditions. Different Working Environments Require Different Screen Panels Of Different Materials.

Modular Screen also Be Named As Modular Sieve.

The Materials Can Be Choose As Rubber , Industry Plastic , Polyurethane ( PU , Urethane )

Our Company Can Produce Modular Screen Or Sieve As Panels , Mesh , Sheet , Plate , Mats , Deck , Cloth , Media , Bends .

The Modular Screen Panels Produced By Hebei Fengmang Technology Co.,Ltd Is Mainly Used In Mineral Screening Process. The Sizes Of Modular Sieve Panels Can Be Processed According To Customers’ Drawings. After Years Of Accumulation, Our Company Has Owned a Large Number Of Models Of Tools, And Provides Services For Different Buyers, Thus Reducing The Cost Of Customers’ Grinding Tools. Modular Sieve Screen Can Be Cut According To Practical Application, So As To Install And Debug Different Machines.

In Order To Increase The Impact Resistance Of Modular Screen Plate, Welded Steel Skeleton Is Usually Embedded In The Screen Mats. However, For Some Environments That Do Not Require Too Much Pressure Bearing Capacity, The Modular Screen Plate Is Not Embedded In Any Skeleton, Instead, The Thickness Of The Modular Panels Is Thinner. Of Course, This Can Greatly Reduce The Weight Of The Modular Mesh, The Machine And Equipment Will Not Be Damaged By Its Own Weight.

The Modular Plate Surface Is Evenly Distributed With Holes Of The Same Size. It Is These Meshes That Play The Role Of Sieving. The Large Particles Remain On The Screen And Flow Into The Heavy Particles Trough, While The Small Particles Smaller Than The Mesh Size Enter The Fine Materials Trough Through Sieving.

Except For The Load-Bearing Steel Skeleton, The Main Material Of The Modular Sieve Panels Is Composed Of Wear-Resistant Rubber Or Wear-Resistant Polyurethane. It Is These Wear-Resistant Rubber Polyurethanes That Provide Wear Resistance.

Working Noise Is Low, Whether Rubber Or Polyurethane, Are Soft Wear-Resistant Materials. Because Of Its Common Elastic Properties, When Hard Materials Hit Rubber Or Polyurethane, The Materials Will Be Bounced Off, And Basically No Sound Will Be Emitted. The Little Sound We Hear Is Just The Sound Of Collisions Between Materials.

Modular Screen Is The Main Component Of The Vibrating Screen Machine, Which Is Laid Flat On The Surface Of The Vibrating Screen Machine For Screening. But It Also Belongs To Wearable Replacement. When The Modular Panels Is Damaged Or Worn Seriously, It Is Necessary To Replace The Screen Plate So That The Work Can Proceed Smoothly.

Modular Panels And Mesh Is Mainly Used For Raw Coal Classification And Ore Separation. When Needed In Coal Yard, Fine Coal Particles Can Make Combustion More Fully. After The Crushing Of The Crushing Machine, The Big Particles Are Broken Into Small Coal Particles, And Then The Small Coal Particles Are Purified. The Wear-Resistant Module Sieve Panels Plays a Vital Role In This Process.

Ore Screening Requires Higher Sieve Screen Plate Weight In This Separation Process. Because The Ore Is Harder Than The Coal, It Is More Difficult To Crush, And The Wear Force Of Classification Is Stronger, So The Requirement Of Sieve Plate Is Higher. Therefore, The Hardness Of Rubber Screen Panels Is Generally 65 Shore A, While The Hardness Of Polyurethane Material Must Be As High As 95 Shore A.