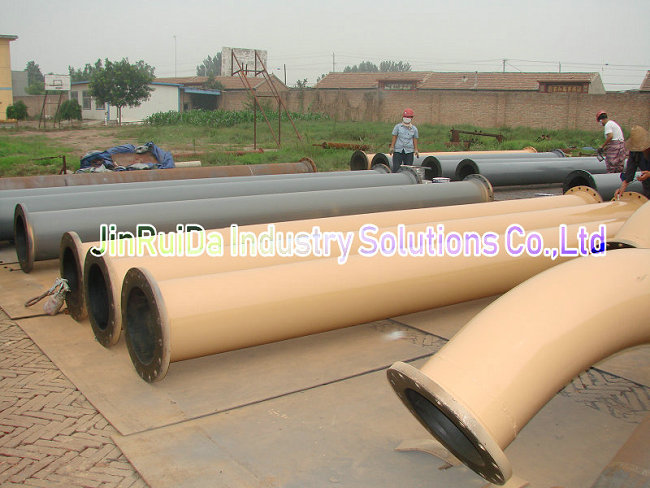

Rubber Lined Pipe Is a Kind Of Composite Pipe Pasted With Hard And Soft Materials.

The External Framework Is Carbon Steel Pipe And Seamless Steel Pipe,

The Inner Layer Is Made Of Wear-Resistant, Corrosion-Resistant And High Temperature Resistant Rubber,

Through The Physical And Chemical Properties Of Rubber Itself, The Effect Of Pipeline Transportation Medium On The External Steel Pipe Is Reduced, Such As Impact Wear. Impact, Corrosion, Etc.

Due To The Buffer Function Of Rubber, The Service Life Of Pipeline Is Greatly Extended And The Cost Of Users Is Reduced.

Working Principle

The Elastic Property Of Rubber Is Used To Relieve The Overall Impact Of External Medium On The Pipeline; The Wear Resistance Of Rubber Lining Is Used To Overcome The Wear Of Corresponding Transmission Medium On The Pipeline; The High Corrosion Resistance And High Temperature Resistance Of Rubber Are Used To Protect The Transmission Pipeline.

Use Advantage

1. Excellent Structure

The Reinforced Skeleton Seamless Steel Pipe Of The Pipe Is Combined With The Rubber Inner Liner With High-Performance Adhesive As a Whole. It Overcomes The Characteristics Of Steel Pipe, Plastic And Rubber, As Well As The Disadvantages Of Frp , Such As Brittleness And Poor Impact Resistance. At The Same Time, It Has The Common Advantages Of Steel Pipe And Wear-Resistant Rubber, With Excellent Comprehensive Cost Performance.

2. High Strength And Impact Resistance

Rubber Elastomer Has Low Density, Light Weight, Good Vibration Absorption Performance And Excellent Mechanical Impact Resistance; It Has High Strength, Good Steel Property And No Creep; It Has Strong Impact Resistance, Earthquake Resistance And Water Hammer Resistance; It Is Convenient For Transportation, Installation And Maintenance.

3. Wide Temperature Range

The Desulfurization Rubber Lined Pipe Can Be Used In The Range Of – 50 Centigrade To + 150 Centigrade For a Long Time, And The Rubber Lining Layer Will Not Be Separated From The Carbon Steel Pipe And Seamless Steel Pipe Due To The Temperature Change.

4. Energy Saving

Good Lubricity, Small Running Resistance Loss, Saving Running Cost. The Rubber Lining Has a Smooth Surface And a Very Low Friction Coefficient. Like Skating, When The Contact Surface Between The Conveying Medium And The Rubber Lining Is Sufficient, The Conveying Resistance Is Only One Tenth Of That Of Different Steel Pipes. So It Greatly Improves The Work Efficiency.

5. Excellent Anti-Aging Performance

Under Normal Use Pressure And Temperature, The General Service Life Is More Than 15 Years (Theoretical Value). The Service Life Of The Pipeline Will Be Longer If It Is Rotated Once At Nearly 90 Angle After 6-8 Years. Rubber Lined Pipe Can Be Repeatedly Used For Rubber Lining For 4 Times, Reducing Cost, Short Production Cycle And Ensuring Construction Period.

Service Life Factor

1. Properties Of Rubber

The Rubber Inner Liner Should Be Determined According To Its Use Environment. If The Physical And Chemical Properties Of The Selected Rubber Do Not Match The Environment, The Service Life Will Be Greatly Reduced, And The Rubber Inner Liner Will Fall Off And Other Serious Consequences.

2. Adhesive Strength Of Rubber And Steel Pipe

The Adhesive Degree Between Rubber And Inner Wall Of Steel Pipe In Non Rubber Manufacturing Enterprises Is Not Strong, Which Will Result In Uneven Stress On Lining Layer, Local Uneven Stress On Conveying Medium And Local Rapid Corrosion Of Rubber Lined Pipe.

3. Working Condition

Different Places Of Use, Corrosiveness, Temperature, Service Strength, Etc. Will Affect The Service Life Of Rubber Lined Pipe. Therefore, Reasonable Analysis Should Be Made For Rubber Lined Pipe At The Beginning Of Selection.

Test

According To The National Rubber Lining Inspection Standard. The Main Tests Are As Follows:

1. Surface Inspection

2. Leakage Detection

3. Thickness Test

4. Hardness Test

Choice Of Manufacturers

1. Own Independent Rubber Production And Inspection Equipment

2、 Rubber Lining Manufacturers Have Relatively Complete Management System

3. Rubber Lined Pipe To Finished Product Inspection Equipment

4. Site Investigation Capacity

5. Independent After Sales Service Team

6. Perfect Rubber Lining Repair System

A Manufacturer Of Rubber Lined Pipe Needs a Relatively Complete System. From Raw Material Selection, Processing Flow, Inspection Equipment, Etc., The General Manufacturer Does Not Have Rubber Production Capacity And Inspection Equipment, Which Makes It Difficult To Guarantee Its Rubber Lined Pipe. The Quality Of Rubber Lined Pipe, Such As The Thickness Of Rubber Plate Or Rubber Performance, Directly Affects Rubber Lined The Use Of Pipe, So In The Selection Of Manufacturers, We Must Choose a Certain Technical Ability Of Manufacturers

JinRuiDa Industrial Solutions Co., Ltd. Has a Complete Set Of Production And Processing Equipment, Which Can Complete All The Production And Processing Parts From Raw Material Production To Finished Products, Without Relying On An Approved External Company To Independently Produce. In Recent Years, Although There Are a Large Number Of Rubber Lined Pipe Manufacturers In The Domestic Market, Because They Do Not Have a Complete Set Of Production, Inspection And Management System, Their Products Often Cause Adverse Consequences To Important Departments Such As Power Plants, So It Is Necessary To Select Production Enterprises With Technical Capabilities.

Bonding And Curing Method

There Are Mainly Two Kinds Of Hot Vulcanization Bonding And Cold Vulcanization Bonding. The Hot Vulcanization Bonding Is Controlled By The Curing Tank At High Temperature, High Pressure And Certain Stability. On The One Hand, The Rubber Can Be Vulcanized By External Conditions, On The Other Hand, The Rubber Can Be Bonded To The Bonding Surface By Hot Vulcanizing Adhesive, And The Cold Vulcanizing Adhesive Is Directly Bonded To The Rubber Plate By Special Vulcanizing Adhesive, That Is, The Adhesive Is Ready For Use. Our Company Is Mainly Through The Heat Curing Process.

Field Of Use

According To Years Of Construction Experience And Different Application Fields, Rubber Lined Pipe Can Be Divided Into Two Categories: One Is That Under The Condition Of Poor Mining Conditions, Imported World-Class Rubber Is Generally Used. Because Their Performance Is Several Times That Of Domestic Rubber, They Can Work In This Environment. Under The Condition Of Good Mining Environment, Domestic Rubber Lined Is Used To Reduce The Cost Of Enterprises Pipe, Can Also Play The Effect Of Application.

As More And More Users Are Familiar With The Superior Performance Of Rubber Lined Pipe, Its Application Fields Can Involve Mines, Factories, Power Plants, Industrial Water Treatment Equipment, Mineral Processing , Paper Industry, Petrochemical Industry, Food Industry, Fertilizer Plant, Medicine And Environmental Protection Industry.

Rubber Lined Pipe | Carbon Steel Piping Rubber Linings

Rubber Lining of Rubber Lined Steel Pipe

Natural Rubber,Poly Urethane Rubber,Butyl Rubber,Nitrile Butadiene Rubber,Chloroprene Rubber,Hypalon Rubber,Ethylene Propylene Rubber,Styrene Butadiene Copolyme Rubber,Synthetic Rubber,Abrasive Rubber,Anti Corrosive Rubber,Acid Resistant Rubber,Alkali Resistant Rubber,Salt Resistant Rubber,High Temperature Resistant Rubber,Oil Resistant Rubber,Vulcanized Rubber,Pre Vulcanized Rubber